1910s

-

1915

- New coal burners are installed and big tube mills set as the plant undergoes improvements. The upgrades lower the cost of production by 10 to 15 cents per barrel.

-

191319151913

1920s

-

1920

- The original method of manually loading raw materials into mule-drawn cars is replaced by eight-ton steam engines and a steam-driven shovel that moves on rail sections.

-

1922

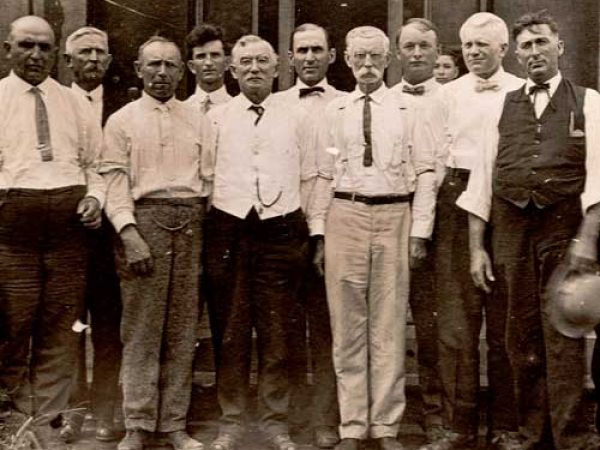

- Monarch announces a payroll of 179 men per day with wages totaling $258,834.51. The Humboldt Union writes, “The Monarch Cement Company has made a good fight through years of adversity and is coming out on top.”

- For the first time since its reorganization, Monarch announces it will pay a 6 percent dividend to stockholders.

-

-

1920192219231924

1930s

-

1933

- The Portland Cement Association awards an 8-foot-tall safety “trophy” (made of concrete, of course) to Monarch in recognition of a perfect safety record for the entire year of 1932.

-

-

1939

- Production employees unionize under the United Cement Lime & Gypsum Workers Union.

193319351939

1940s

-

1942

- Monarch earns safety honors again as the Portland Cement Association recognizes the plant for a perfect safety record for five consecutive years.

-

1945

- Fred Rhodes retires, and Walter H. Wulf is elected president of Monarch.

-

1949

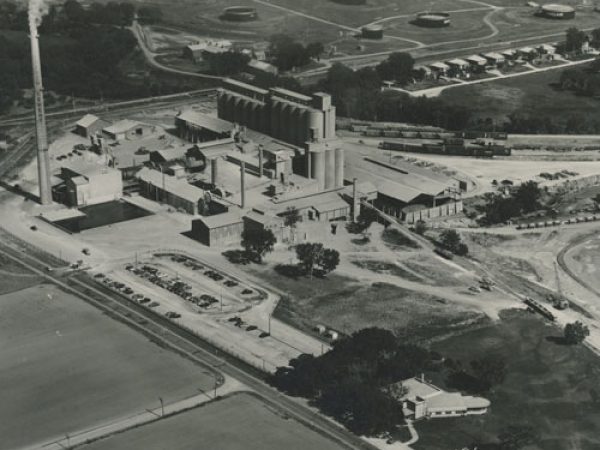

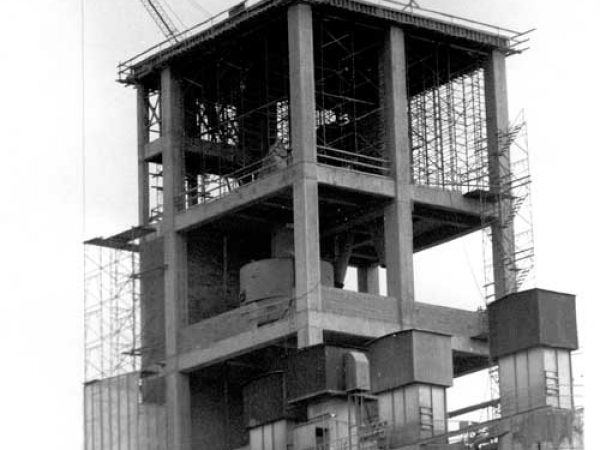

- A new 426-ton kiln is installed, part of a $1.5 million expansion. Draft, temperature, motor speed, cooler speed, steam and flow of gas are all controlled through a single instrument panel.

1941194219451949

1950s

-

-

1952

- A new type of explosive that better protects workers and eliminates drilling is tried at the Monarch plant. The “shaped charge” prevents flying rock typically caused by dynamite and allows employees to be much closer to the detonation.

-

-

1956

- Monarch employees receive an 18-cent-an-hour pay increase, part of an agreement negotiated between the plant and Local 93 of the United Cement, Lime and Gypsum workers.

- The Company announces a $6.5 million expansion, adding 50% more capacity to the plant—from 1,500,000 to 2,250,000 barrels of cement annually.

1951195219531956

1960s

-

-

-

1965

- Monarch acquires Salina Concrete Products Inc. in Salina, Kansas.

196819691965

1970s

-

-

1975

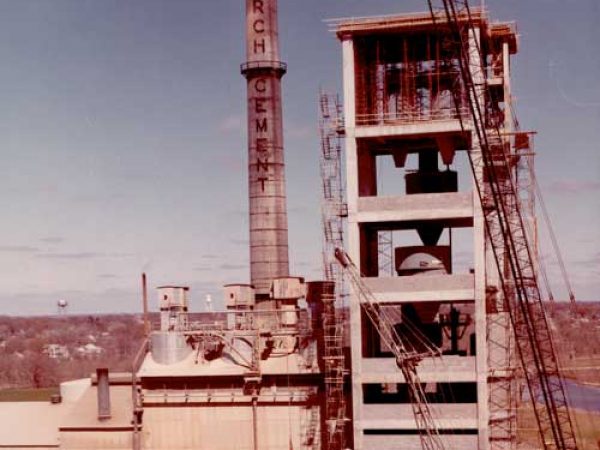

- Monarch begins efficiently burning clinker in two four-stage suspension preheater kilns. These kilns preheat the raw materials prior to entering the kiln and thereby use available heat that otherwise would be vented into the atmosphere. The roller mill efficiently uses all but about 200° of the available heat.

-

1977

- Monarch acquires Concrete Materials Inc., located in Merriam, Kansas.

197119751977

1980s

-

1980

- Jack R. Callahan is named President upon the retirement of Charles Fussman.

-

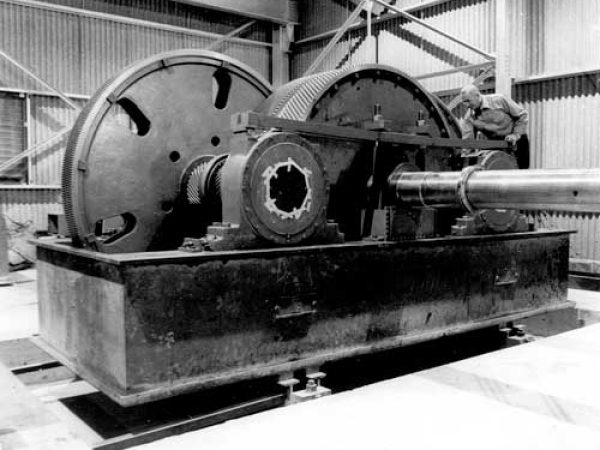

1983

- Construction begins on a roller mill system to process raw materials, such as limestone and shale. Once the roller mill system is complete, the raw mills are converted to swing mills, allowing them to grind either raw materials or clinker into cement, thus increasing overall production capacity.

-

1986

- The Company acquires Concrete Enterprises Inc. (Hutchinson, Kansas), Kansas Sand and Concrete Inc. (Topeka, Kansas) and Kansas Building Products (Wichita, Kansas).

- Management elects to serve the Iowa market by transferring clinker produced in Humboldt to its Des Moines plant for grinding into finished cement, leading to an appreciable reduction in costs.

198019831986

1990s

-

1994

- Monarch begins purchasing foreign clinker to supplement production to fulfill its customers’ demand for cement.

-

-

1997

- Walter H. Wulf Jr. is elected to the presidency of Monarch by the Board of Directors, following the retirement of past president Jack Callahan.

199419951997

2000s

-

2001

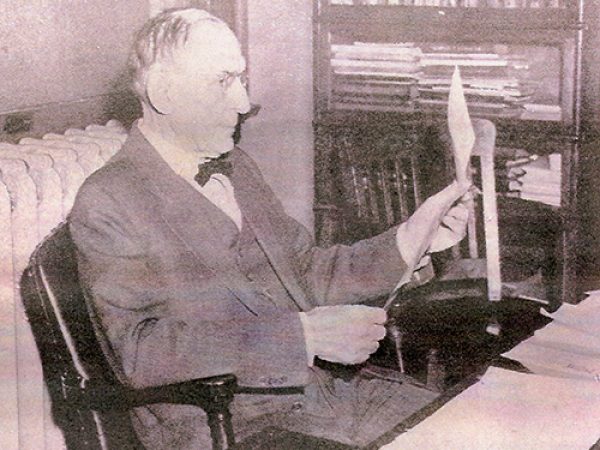

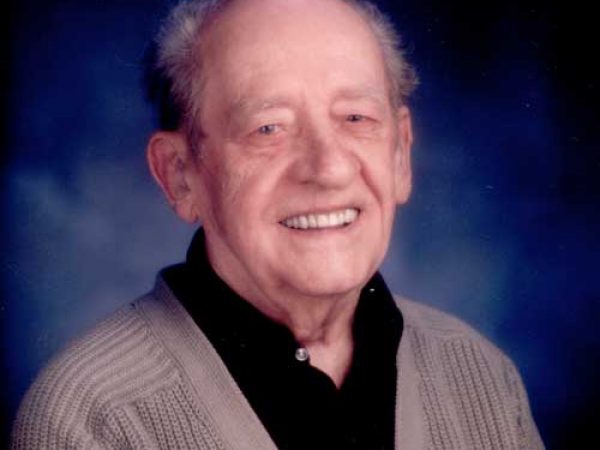

- Walter H. Wulf dies at the age of 101 after serving as a Monarch employee for more than 80 years of his life. His office desk is donated to the Humboldt Historical Museum as part of the Monarch display.

- To eliminate the need to purchase foreign clinker to keep up with demand, Monarch commits to another expansion project to increase production by 40 percent.

- Monarch acquires Capitol Concrete Products Co. Inc. in Topeka, Kansas.

-

2002

- The Company acquires a new subsidiary, Joplin Concrete Company Inc., in Joplin, Missouri.

-

2005

- The Monarch Medical Clinic opens its doors to provide on-site medical services to employees and their dependents covered under the provided health plan.

200120022005

2010s

-

2011

- Monarch acquires Kay Concrete Materials Co. in Monett, Missouri.

-

2014

- Monarch deregisters from the Securities and Exchange Commission (SEC).

-

201120142015

2020s

-

2020

- Declaration of the COVID-19 Pandemic, March 13, 2020. Annual Stockholder’s meeting went live-streamed for the first time in history due to COVID-19.

- Monarch closed Salina Concrete Products in Salina, KS, and consolidated operations in Wichita, KS

- Monarch awarded the 2020 Safety Innovation Award by the Portland Cement Association.

-

-

202020212022